Optimize Your Brewing Process with Omega’s Vast Selection of High-Quality Products

Whether we are talking about a large-scale beer-brewing operation or a small, independent craft brewery, top brew masters can all agree on one thing: quality is king.

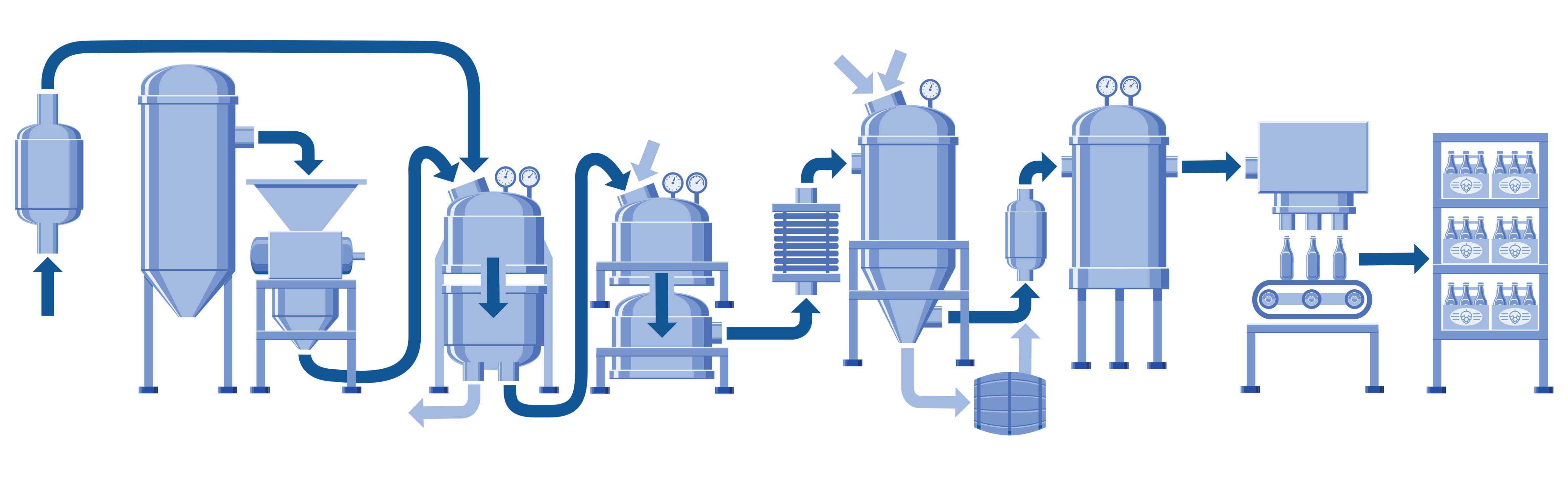

In order to brew the all-allusive, perfect beer, both effective monitoring and effective control of systems – from the start of the brewing process all the way to the finish – are absolutely necessary. Brewers are constantly seeking out products and process solutions that can help them achieve the high level of quality their industry demands – and more and more, professionals in the brewing industry are turning to Omega products for their innovative technology, high-quality, and reliability.

Omega Engineering: A Brewer’s Engineering Company

Omega Engineering has the sensing solutions and expert know-how to optimize any brewing process. From water filtration to fermentation to canning to storage and transport, Omega manufactures products ideal for the measurement and control of such sensing variables as temperature, pH, and pressure within any brewing environment.

Temperature

HANI High Accuracy, Non-Invasive Clamp Temperature Sensor

Omega’s new and innovative HANI High Accuracy, Non-Invasive Clamp Temperature is a game-changer for the brewing industry.

That’s because HANI sensors do what few thought was even possible: they measure, with very high accuracy, the temperature of moving fluid inside a pipe without the use of an invasive temperature probe. The HANI simply clamps to the outside of the pipe and measures temperature inside the pipe, accurately, in seconds. There’s no need to cut, weld, drill, or shut down production to install or relocate a HANI sensor. And HANI sensors never come in contact with product, so there’s no risk of contamination or turbulence.

The HANI High Accuracy, Non-Invasive Clamp Temperature Sensor can be used to:

- Monitor temperature in incoming water filtration and sanitization

- Check for in-line heat loss from the lauter tun to the boil kettle

- Monitor cooling lines during wort cooling

- Audit temperatures at the bottling line without adding turbulence

3-A Sanitary Temperature Probes

If a fixed temperature sensor is needed, an Omega 3-A sanitary temperature probe can be installed wherever temperatures need to be monitored within the brewing system. The 3-A approved Omega PRS-S-NB9W and PRS-H-NB9W Series RTD Sensors are designed for use in sanitary or hygienic clean-in-place applications – and are ideal for the brewing industry.

These sensors are manufactured with 316L stainless steel housings that meet the dimensional and finish requirements of 3-A standard 74-05 and ASME BPE-2001.

The PRS-S-NB9W and PRS-H-NB9W Series RTD Sensors are welded and processed to provide a clean, smooth, 32 microinch (or better) surface finish in the wetted areas for clean-in-place processes. In addition, the probe stems are manufactured in two configurations; with a standard 1/4" diameter probe for standard duty service, and a stepped 3/8" to 3/16" diameter probe design perfect for good response times in heavy duty applications. A white polypropylene connection head provides a convenient 3/4" NPT threaded connection point for process wiring.

3-A Sanitary Temperature Probes can be used to:

- Monitor temperature in incoming water filtration and sanitization

- Check for in-line heat loss from the lauter tun to the boil kettle

- Monitor temperature during the fermentation process

- Monitor temperatures at the bottling line

Flow

G2-Series Brewery & Food Indicating Flow Meters

Make your recipe perfect every time. With a G2-Series high-temperature brewery and food indicating flow meter, there’s no more need for “eye-balling” levels. Simply put, this sanitary flow meter is the best flow meter for brewing processes – it is highly dependable and affordable, making it a great choice large-scale and small-batch brewers alike.

The G2-Series is extremely repeatable so quality control is easy to maintain. Whether you measure strike water, sparge water, wort transfer to the fermenter, or your final batch volume, the G2 can help at all grain brewing stages. The G2-Series is available as a Rate and Total Flow Indicator only, or with Indication and 4-20 mA and Pulse outputs.

G2-Series High-Temperature Brewery and Food Indicating Flow Meters can be used to:

- Measure and monitor flow in incoming water filtration and sanitization

- Check for in-line heat loss from the lauter tun to the boil kettle

- Measure and monitor flow in mashing and wort boiling

- Measure and monitor flow in the canning and bottling

pH

PHCN37 Panel Mount pH Controller

This microprocessor-based family of pH panel mounted controllers is designed for a wide variety of environmental monitoring applications – and is perfect for beer brewing. The units feature either automatic or manual temperature compensation of pH, two 5 amp mechanical relays and a choice of scalable 4 to 20 mA, or 0 to 20 mA control or recording output or a 0 to 10 V output. For ease of operation, all calibration and parameter setpoints are selectable through the front keypad. The PHCN model can be interfaced with a variety of pH electrodes.

The PHCN37 Panel Mount pH Controller can be used to:

- Monitor pH in water filtration and sanitization

CDCN-961 Conductivity, Resistivity, or TDS Controller

An Omega CDCN Series conductivity, resistivity, or total dissolved solids (TDS) controller can help to ensure that incoming water is perfect for whatever type of beer is being brewed.

These controllers are designed for in-line monitoring of process solutions and water applications. They have simple menu driven programming for easy set-up and available relays can be programmed for control, alarm, or as a calibration reminder. The transmitter output is also programmable from the keypad eliminating the need for potentiometer or dip-switch settings. The calibration function automatically recognizes the buffer solution resulting in a simple and straightforward system calibration.

The CDCN-961 Conductivity, Resistivity, or TDS Controller can be used to:

- Monitor water filtration and sanitization processes

Layer N SS-001 IIoT Environmental Sensors

Monitor environmental conditions throughout the entire brewery and access the data from the cloud anywhere, anytime with an Omega Layer N IIoT smart environmental sensor.

Layer N SS-001 Smart Sensors utilize precision internal sensing elements to accurately measure environmental conditions for a wide range of applications. The SS-001 utilizes sub GHz Frequency Hopping Spread Spectrum (FHSS) technology to ensure robust, long range communications. And Layer N Smart Sensors are easily paired to the Layer N Gateway with the press of a button, and will automatically show up on your Layer N Cloud Account. Reports, histories, and e-mail alerts from the Layer N Cloud keep you informed on the status of all your vital processes.

Layer N wireless products are designed with state-of-the-art security features to protect your data with robust AES256 encryption and advanced PKAEC521 bit (NIST) elliptic-curve cryptography to protect your data.

Advanced features may be configured through SYNC software and include selective data extraction, measurement and device traceability, local alarms, and adaptive transmission rates to reduce data congestion and extended battery life.

Layer N SS-001 Smart Sensors can be used to:

- Monitor environmental conditions during malting, kilning, and milling

- Monitor environmental conditions during the processing of hops

- Monitor environmental conditions during the finishing/carbonation process

LVCN 6000-7000 Capacitive RF Single Point Level Switches

Keep process media levels under control with an LVCN 6000-7000 series capacitive RF single point level switch. These level switches are ideal for low- and high-level detection for both liquid and solids. The LVCN 6000/7000 series can also detect level through a sight glass – meaning there is no contact with the product.

Unlike other capacitance probes, the LVCN 6000/7000 series can detect any type of conductive, non-conductive, or low dielectric materials with extremely accurate performance, almost complete immunity from build-up, temperature changes, or condensation.

The LVCN 6000/7000 series is a compact switch that can be made with many types of process connections, such as threaded flange or sanitary, and is made with rigid rod or cable – and both can be supplied in extended versions.

LVCN 6000/7000 Capacitive RF Single Point Level Switches can be used for:

- Control media levels during malting, kilning, milling

- Control media levels during the processing of hops

- Control media levels during fermentation

- Control media levels during finishing and carbonation

- Control media levels during canning and bottling

2-Wire Isolated Dissolved Oxygen Transmitter

An Omega 2-Wire Isolated Dissolved Oxygen transmitter can help ensure consistent fermentation and minimum beer loss in excess yeast. The 3-electrode amperometric sensor produces a current output that is proportional to the partial pressure of oxygen. The entire reaction cell of the transmitter is housed in a replaceable PEEK cartridge, which makes sensor regeneration fast and simple. An integral preamplifier is encapsulated in the body of the sensor. This creates a low impedance signal output which ensures stable readings in harsh environments, and maximizes the distance between sensor and transmitter.

2-Wire Isolated Dissolved Oxygen transmitters can be used to:

- Ensure consistency in the processing of hops

- Ensure consistency in fermentation

OM-EL-21CFR-Series USB Data Loggers

Omega OM-EL-21CFR Series data loggers can ensure cold chain compliance during storage and transport of your precious final product. These data loggers log temperature data from your dock, to the distributors warehouse, and all the way to the local pub.

The OM-EL-21CFR Series data loggers are capable of storing between 16,000 to 32,000 temperature or humidity readings and offer models with internal temperature sensors as well as external probe attachments which allow for a wider temperature sensing range.

OM-EL-21CFR-Series USB Data Loggers can be used for:

- Ensuring cold chain compliance during storage and retail transport

Pressure

PSW2100 Electronic Pressure Switch

Protect sensitive filtration components in any size brewing system from high water pressure with Omega’s PSW2100 electronic pressure switch.

These electronic pressure switches feature a fully programmable digital interface with mono-silicon sensor technology. Set-up and programming are painless – with the use of three keys and a premium, easy-to-read 1” wide 5-digit OLED display. Visibility is maximized with a display capable of rotating 350 degrees and also with two LEDs providing visual alarms. With the rotation capabilities and a rugged, well-protected IP67 housing rating, this pressure switch is capable of high performance in a wide variety of environments and installation positions. These features, coupled with high accuracy, make this pressure switch a premium, user-friendly option for pressure measurement and monitoring.

PSW2100 Electronic Pressure Switches can be used to:

- Control pressure in water filtration and sanitization

PX409S Configurable, High-Accuracy Sanitary Pressure Transducers

An Omega PX409S Configurable, High-Accuracy Sanitary Pressure Transducer can help keep tabs on process media (AKA beer) within a brewing system.

These high-accuracy pressure transducers have a proven record in high-performance commercial and aerospace applications for over 25 years. A full Wheatstone bridge is diffused into a silicon wafer and then micro-machined to exacting standards to produce a silicon sensor that has excellent stability, linearity, repeatability, and excellent long-term stability. At our state-of-the-art facilities, transducers are calibrated using extremely high accuracy equipment, and a 5-point NIST traceable calibration certificate is included with each model.

All stainless-steel parts, welded construction, and premium temperature compensation makes these transducers suitable for use in tough industrial environments – capable of withstanding any needs your brewing system may have. And Omega’s free, downloadable software (?) provides advanced data-logging capabilities – adding value and flexibility to your transducer performance.

PX409S Configurable, High-Accuracy Sanitary Pressure Transducers can be used to:

- Monitor process media pressure levels of incoming water filtration

- Monitor process media pressure levels during boiling and fermentation

PX3005K Sanitary Pressure Transmitters

Omega’s PX3005K is a compact, rangeable, digital sanitary pressure transmitter that is ideal for monitoring pressure in any brewing process where a flush diaphragm is required. The rugged 316 stainless-steel enclosure is IP67 rated, making it suitable for washdown environments. A 5-digit backlit LCD allows for full precision representation of process variable.

This hygienic design has been issued 3-A symbol authorization and meets the requirements of the 3-A Sanitary Standards – making it the best choice for process automation and tank level applications where consistent reliable pressure management are essential.

PX3005K Sanitary Pressure Transmitters can be used to:

- Monitor pressure in malting

- Monitor pressure in the kilning and milling processes

From incoming water filtration all the way to the shipping dock, the key to success in brewing is consistency, and the key to consistency is fast and accurate process measurement and control from Omega Engineering.