Introduction

The Industrial Internet of Things (IIoT) consists of networked devices creating systems that can monitor, collect, exchange, and analyze data to enable smarter, faster business decisions for industrial companies. The benefits of applying IIoT approaches to industrial business problems are huge as even a small percentage improvement in efficiency, time, capital expenditure, or asset allocation translates into significant savings and/or revenue enhancement. Below, we explore two typical use cases and corresponding real-world examples of IIoT monitoring solutions.

Environmental Monitoring

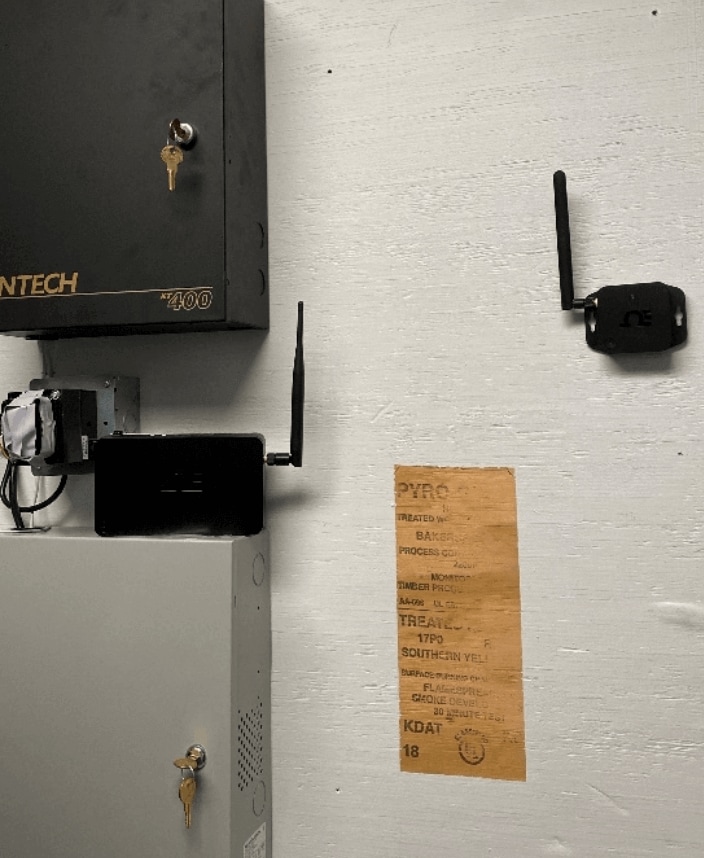

Maintaining proper temperature, humidity, air quality, and gas levels such as CO2 are critical for worker safety, process stability, material management, and equipment longevity. While sensors may already be in place, the information often remains on a display or a local PC. With IIoT, that information now becomes available remotely and in real-time, permitting faster reaction to alarm conditions, especially when the person monitoring is not in the same location.

In the real-world example below, we show a network/server IT equipment room. It’s important that temperature and humidity be monitored to ensure they remain at the desired levels. The IIoT solution consists of a temperature/humidity sensor (the small black box with antenna at the right in the photo below) and a gateway (the larger black box with antenna to the left). The real-time temperature/humidity data is transferred from the sensor through the gateway to secure cloud storage. Authorized users can access this data from any location with an internet connection via a laptop or mobile device browser. In addition, cloud-based software analyzes the data for alarm conditions (i.e., high temperature or humidity) and notifies the appropriate personnel for action.

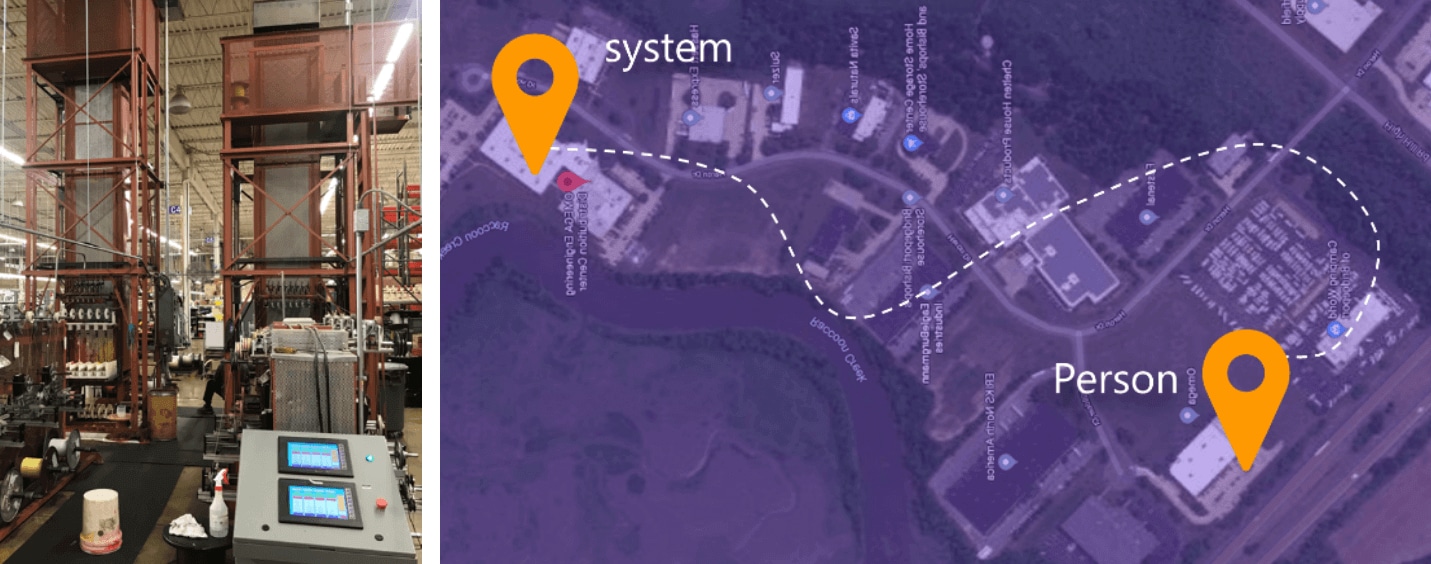

Process Monitoring

IIoT enhances process automation by moving the sensing and control information centrally to secure cloud storage for analysis by machine learning and statistical analysis algorithms. An immediate benefit is the enablement of remote monitoring. An additional benefit, since the data is centralized, is that the information from multiple machines, workcells, and locations is available for analysis. The results of this aggregated data analysis enable predictive maintenance, process optimization, and performance benchmarking between workcells and plants. Note that the IIoT solution installs as either an enhancement or a replacement to the existing automation system.

In the real-world example below, we have a system shown in the left photograph. The monitoring station is shown in the lower right of the photo. In the right photograph, we see that the person who monitors this process is located in a different building some distance away from the building with the process control system. This person therefore had to physically go to the other building on a regular basis to check on the process. The IIoT solution was to connect a gateway (same as in the example above, not shown here) to the existing process controller. The process data moves from the controller through the gateway to secure cloud storage. The process data is now available to the person in the other building via their laptop and web browser.

Conclusion

The benefits of IIoT directly apply to environmental and process automation monitoring. These benefits derive from centralizing the collected information in secure cloud-based storage. Once centralized, the information can be analyzed and the results of that analysis (tables, graphs, alarms, notifications) made available to authorized users wherever they are located. Getting the data from the system to the user is better, faster, and cheaper than getting the user to the system to look at the data.